D.M.P. Engineering Works has been a recognized brand in industrial machinery since 1993. We have a premium selection of High Pressure Triplex Plunger Pump which are fit for the most demanding industrial work. These pumps have been proven to be efficient and reliable not only because of their durability, but also because they can operate under high pressure in a wide variety of areas including chemical processing, water treatment, soap and detergent, and many more.

A High Pressure Triplex Plunger Pump is defined as a positive displacement reciprocating pump with three plungers that sequence for a continued flow of liquid at high pressure. The working cycle for the plunger pump consists of an intake stroke, in which liquid is drawn into the pump chamber, and discharge stroke in which the liquid then is discharged under pressure through the outlet valve. The flow rate of the liquid is directly proportional to the Strokes per Minute (SPM) of the pump, and provides the most precise control.

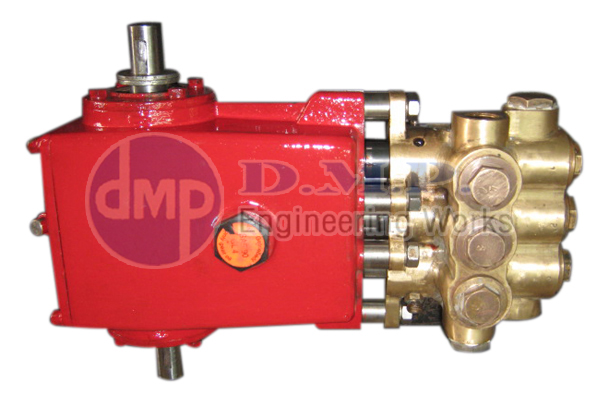

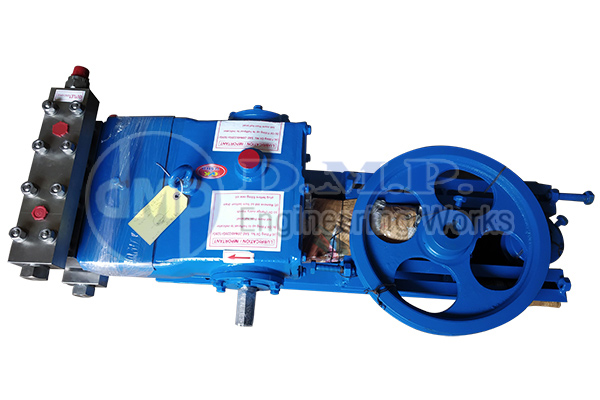

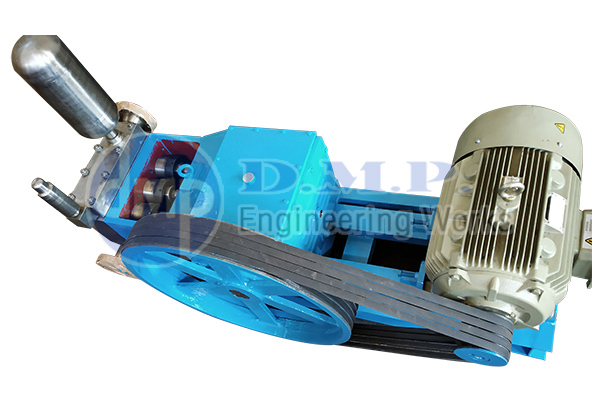

D.M.P. Engineering Works triplex plunger pumps are made with high strength components and precision materials, including concentric ceramic plungers and pre-set packing’s, which provide dependability even under the most challenging conditions. These pumps reach pressures of up to 700 kg/cm²; they are used for hydro jetting, pressure washing, water blasting, chemical dosing, descaling, misting, and many other industrial cleaning and transfer projects.

With over thirty years of experience, we also manufacture a variety of soap machinery spares, rotary unions, hydraulic machine parts, silicate conveyors, and compatible parts for brands such as ACMA, Binacchi, Mazzoni, Khosla, and Packona.

High Pressure Plunger Pumps are positive displacement triplex piston pumps. In a reciprocating pump, a volume of liquid is drawn into the cylinder through the suction valve on the intake stroke and is discharged under positive pressure through the outlet valves on the discharge stroke. The flow rate of pump is directly proportional to its SPM (Strokes Per Minute). Pressure Jet high pressure plunger pump have three synchronized plungers that discharge liquids at high pressure with minimum pulsation. Our high pressure pumps include both industrial High Pressure Piston Pump and High Pressure Plunger Pump designs.

Here, pistons are reciprocated using crankshaft, not cam. The piston pump design with mechanically actuated inlet valves and moving piston cups permit strong suction and pressures up to 100 kg/cm2. The plunger pump design with pre-set packings and concentric ceramic plungers provide high pressures up to 700 kg/cm2 (10,000 psi) and multiple head and drive options. Our extensive range of industrial high pressure piston pump and high pressure pump provides just the most suitable pump as per specific requirement of flow rate & pressure for thousands of tasks including washing, cleaning, water jetting, hydro blasting, hydro testing, hydro jetting, wet sandlasting, splitting, sewer cleaning, transfer, reverse osmosis, descaling, deburring, misting, injecting and dosing. Our industrial triplex reciprocating plunger pumps are operating in harsh seawater desalination systems, reclaim car washing/vehicle cleaning, hydrostatic accumulator charging and multi-station central cleaning systems. Maintenance and production managers specify Pressure Jet industrial high pressure pumps because they are extremely reliable, efficient, dependable, easy to maintain and provide long life.

| TECHNICAL SPECIFICATION | |

| Flow | 153 lpm (40.41 gpm) |

| Working pressure | 65 bar (943 psi) |

| Inlet pressure | Flooded to 3 bar (43.5 psi) |

| Motor hp | 30 hp |

| Speed | 300-715 rpm |

| Plunger dia | 45 mm |

| Max. liquid temp. | 90o C (194oF) |

| Oil capacity | 3.4 ltr |

| Weight | .162 kg Aprx. |

| Over all dimension (mm) | 625 x 455 x 300 |

Beacon Type High Pressure Pump

| TECHNICAL SPECIFICATION | |

| Flow | 189 lpm (50 gpm) |

| Working pressure | 50 bar (725 psi) |

| Inlet pressure | Flooded to 3 bar (43.5 psi) |

| Motor hp | 30 hp |

| Speed | 300-715 rpm |

| Plunger dia | 50 mm |

| Max. liquid temp. | 90o C (194oF) |

| Oil capacity | 3.4 ltr |

| Weight | . 162 kg Aprx. |

| Over all dimension (mm) | 625 x 455 x 300 |

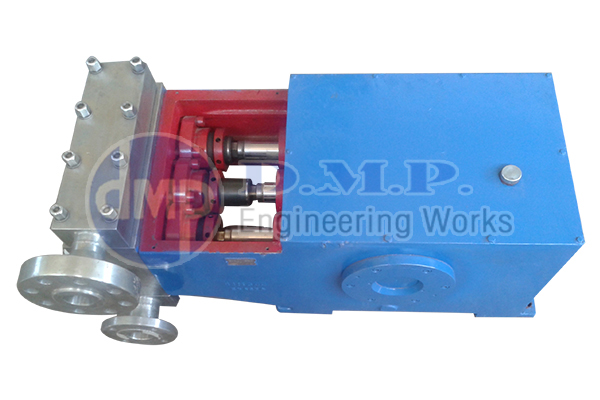

Speck Kolben Type High Pressure Plunger Pump For Boiler

| TECHNICAL SPECIFICATION | |

| Flow | 58 lpm max |

| Working pressure | 110 bar |

| Inlet pressure | Flooded to 3 bar (43.5 psi) |

| Motor hp | 13.1 kw |

| Speed | 1100 rpm |

| Plunger dia | 30 mm |

| Max. liquid temp. | 70o C |

| Oil capacity | 3.4 ltr |

| Weight | . 30 kg Aprx. |

| Over all dimension (mm) | 440×300 |